Pricing Information For Custom Cryogenic Services

We Treat a Wide Range of Products including but not limited to: receptacles, connectors, wire/cable, transformers, circuit breakers and more. We specialize in cryogenic processing for audio parts only, we do not process steel or any sort of tooling or engine parts. Your parts will always be handled by a caring, knowledgeable person in a safe and secure environment that is spotlessly clean. On-site processing allows us to turn your parts around quickly with minimal handling.

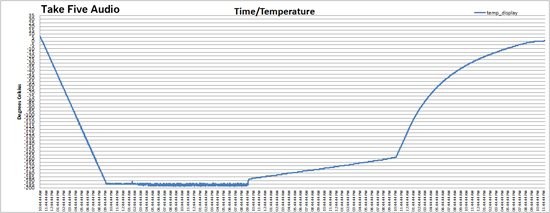

All of our custom processing is returned to the customer with a detailed log printout that shows the complete cycle including ramp down, soak and ramp up. Your parts go in the processor at ambient temperature and are removed at ambient temperature when the cycle is complete, thereby eliminating the risk of damaging thermal shock and frost formation caused by moist warm air contacting extremely cold parts. Below is an example of the log our customers receive with our long processing cycle which is typically used for all our cable, wire and parts. Click on the image for a larger view.

When looking at the graph you can see four distinct patterns in the temperature display. From left to right the first slope is the ramp down, precise control of the temperature is evident in the smooth slope.

The next flat section is the soak, this continues for 12 - 24 hours depending on the profile and materials in the chamber. During this time the items in the processor are submerged in the Liquid Nitrogen and the variations in temperature indicated are measured in the 2 inch space between the surface of the Liquid Nitrogen and the top of the chamber. The actual parts are at a constant temperature because they are submerged.

The next phase is "ramp up", when the application of LN2 is stopped you will see an immediate bump up in the temperature and then a slow ascent over the next 25 hours or so. The immediate bump is due to the fact that the LN2 is no longer being sprayed into the chamber, this causes the temperature in the space between the surface of the LN2 and the bottom of the lid to rise. At this point the LN2 begins to boil off, it will take about 25 hours for all the LN2 in the chamber to boil off which is tracked by the slow upward movement in the graph.

During this phase the items in the bottom of the chamber remain submerged until all the LN2 is vaporized. These items will have been submerged in the LN2 for around 40 - 50 hours depending on the profile, we have found certain items benefit from being placed in this area of the chamber due to the long soak time.

We have made a short video that actually shows the LN2 level inside the processor when the ramp up stage begins and again one hour and twelve minutes later. As you can see in the video it takes quite some time for the level to drop, the recorded vapor temperature in the chamber during this time ranged between -188 C and -187 C but as you can see the products inside were still completely submerged in LN2 at -195 C.

The next area of the graph shows the temperature rising more quickly, this is because there is no longer any LN2 in the chamber, with no source of cold the inside of the chamber rises to ambient much like a deep freeze that has been unplugged.

Depending on the profile used and the ambient temperature, the entire process from start to finish can take about 80-90 hours.

With any sort of process that involves extreme temperature variations there are risks. We take every precaution to ensure the success of every load we process. This does not mean we cannot have a part fail using our process, extreme cold is an excellent way to find material weaknesses. For this reason we require every customer sending us materials for cryogenic processing to enclose a signed copy of our release form. When you sign and enclose this form with your parts you are accepting responsibility for any damage that could possibly occur during the process. Your parts will not be run until we receive a signed original copy of the release, be sure to enclose it with your parts to avoid processing delays. The release form can be found HERE.

Our processing runs are always started on Thursday and finish on Monday. This means items received on Monday will ship back to the customer on the following Monday, items received later than Monday will go into the next scheduled run.

Our Pricing is done by three different methods, per cubic inch, per item and in special cases by weight. We feel this is the best way to service customers that only want a few items done such as cables or small parts, and at the same time offer a quick and easy way for our customers to calculate the cost of getting numerous items of various sizes done. We do not price by the pound normally, this method is only used when treating an item which is small but very heavy, such as a transformer.

Our Cubic Inch Price is $0.75 CDN, cubic inches are calculated on the outside dimensions of the box containing the parts. For instance if you send us a box of parts that measures 8"X5"X4" the cost will be the volume of 160 cubic inches multiplied by $0.75 which comes to $120.00 CDN. Most boxes of parts will be unpacked when put into the processor to ensure full contact with the LN2 unless the customer specifically asks us not to. With cubic inch pricing there will be a minimum $50.00 CDN charge.

Our Prices Per Item:

- Interconnect: $35.00 per pair up to 2M long and 10mm Dia.

- Speaker Cable: $55.00 per pair up to 2M long and 20mm Dia.

- CDs and DVDs: $5.00 ea.

- Phono Cable: $20.00 ea.

- Digital cable: $20.00 ea.

- Powercords: $40.00 up to 2M long and 20mm Dia.